Methods for copper smelting

Release Time:

2025-05-29

Copper ore mined from copper mines is beneficiated into copper concentrate or copper sand with higher copper content. Copper concentrate needs to be smelted into refined copper and copper products.

Copper Smelting Process:

The development of copper metallurgy technology has gone through a long process, but to this day, copper smelting is still dominated by pyrometallurgy, accounting for about 85% of the world's copper output. Modern hydrometallurgy technology is gradually being promoted, and its introduction has greatly reduced the cost of copper smelting.

1. Pyrometallurgical Copper Smelting

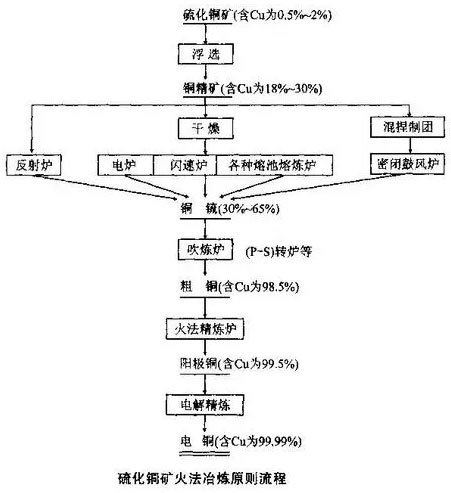

Cathode copper, or electrolytic copper, is produced through smelting and electrolytic refining, generally suitable for high-grade copper sulfide ores. Pyrometallurgical smelting generally involves first beneficiating raw ore containing a few percent or permille of copper to 20-30% as copper concentrate, then conducting matte smelting in a closed blast furnace, reverberatory furnace, electric furnace, or flash furnace. The resulting molten matte (blister copper) is then sent to a converter for blowing into crude copper, and then undergoes oxidative refining and impurity removal in another reverberatory furnace, or cast into anode plates for electrolysis to obtain electrolytic copper with a grade as high as 99.9%. This process is short, highly adaptable, and can achieve a copper recovery rate of 95%. However, since sulfur in the ore is discharged as sulfur dioxide waste gas during the matte production and blowing stages, it is difficult to recover and can cause pollution. In recent years, methods such as the Baiyin process and Noranda process for bath smelting, and Japan's Mitsubishi process have emerged, and pyrometallurgical smelting is gradually developing towards continuous and automated production.

Besides copper concentrate, scrap copper is also a major raw material for refined copper, including old scrap copper and new scrap copper. Old scrap copper comes from old equipment and machinery, abandoned buildings, and underground pipelines; new scrap copper comes from copper scraps discarded by processing plants (the yield ratio of copper materials is approximately 50%). Generally, scrap copper supply is relatively stable. Scrap copper can be classified into: bare miscellaneous copper (grade above 90%); yellow miscellaneous copper (electrical wire); copper-containing materials (old motors, circuit boards); and copper produced from scrap copper and other similar materials, also known as recycled copper.

2. Hydrometallurgical Copper Smelting

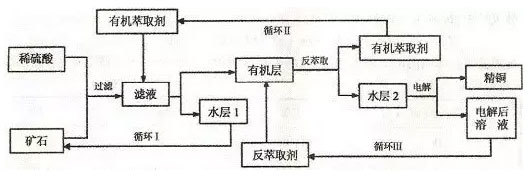

Generally suitable for low-grade oxidized copper, the refined copper produced is electrowon copper. Modern hydrometallurgical methods include sulfating roasting-leaching-electrowinning, leaching-extraction-electrowinning, bacterial leaching, etc., suitable for heap leaching, vat leaching, or in-situ leaching of low-grade complex ores, oxidized copper ores, and copper-containing waste ores. Hydrometallurgical technology is gradually being promoted, and it is expected to reach 20% of total production by the end of this century. The introduction of hydrometallurgical smelting has greatly reduced the cost of copper smelting.

The process flow diagram is as follows: Among them, copper extraction (the process of copper entering the organic phase from the aqueous phase) and stripping (the process of copper entering the aqueous phase from the organic phase) are important technological means in modern hydrometallurgical copper smelting.

Related Information